The Art of the Cure: A Guide to Concrete Strength

The concrete truck has pulled away, and your new patio, driveway, or foundation is perfectly poured and finished. It’s a moment of satisfaction after weeks of planning and hard work. But what happens now? As you admire the smooth, gray surface, the most critical phase of your project is just beginning: the cure.

This waiting period is where your concrete develops the strength and durability to last for decades. Misunderstanding this process is one of the most common and costly mistakes a homeowner can make. At Concrete Gilbert, we believe an informed customer is a successful one. We do more than just deliver high-quality concrete; we partner with you to demystify the curing process, ensuring your investment stands strong against time and the elements.

Curing vs. Drying: It's All About Chemistry

The first and most important concept to grasp is that concrete does not "dry" like paint. It undergoes a chemical process called hydration. This isn't just a technicality; it’s a fundamental reaction that defines the material's final strength.

- Drying is the simple evaporation of water from a surface. If concrete just dried out, it would become weak, dusty, and brittle.

- Curing is the chemical reaction between water and cement particles. During hydration, these particles form strong, interlocking crystalline bonds. This growing crystal structure is what gives concrete its incredible density and compressive strength.

For concrete to reach its maximum potential, it must retain enough moisture to fuel the hydration reaction. Curing isn't about getting water out; it’s about keeping water in for as long as needed. This is why you will often see professionals covering new concrete with plastic or spraying it with water—they are actively managing the cure.

The Concrete Curing Timeline: From Fragile to Formidable

While there is no single magic number, concrete curing follows a generally accepted schedule. Understanding this timeline is key to knowing when your new slab can handle different types of use.

24 to 48 Hours: The Initial Set

After the first day or two, the concrete is typically hard enough to be walked on carefully. It is still considered "green" and is highly susceptible to damage. Scuffing from shoes, gouges from a dropped tool, or paw prints from a pet can become permanent fixtures at this stage. It’s a critical time to protect the surface.

7 Days: Significant Strength Gained

After about a week, the concrete will have reached approximately 70% of its final specified compressive strength. For a new driveway, this is the absolute minimum time you should wait before driving a standard passenger vehicle on it. At this point, the slab can handle moderate stress.

28 Days: The Industry Standard for "Full Cure"

The 28-day mark is the industry benchmark for concrete reaching its designed strength (e.g., 4,000 PSI). By this point, the hydration process has slowed dramatically. For most practical purposes, the concrete is considered fully cured and can handle its intended load, including heavy trucks, RVs, or the placement of large structures like sheds or hot tubs. It is important to remember that hydration never truly stops. Concrete will continue to cure and get infinitesimally stronger for years, as long as moisture and unhydrated cement particles are present.

How Concrete Gilbert Helps You Navigate Key Factors

A 28-day timeline is a guideline, not a guarantee. The intense Arizona climate and other variables can significantly alter the curing process. The team at Concrete Gilbert helps you account for these factors for a successful outcome.

1. Weather and the Gilbert Sun

Temperature is the single biggest factor affecting the cure. The ideal temperature range is between 50°F and 90°F.

- Hot Weather: The high temperatures in Gilbert accelerate the hydration process, but they also cause water to evaporate too quickly. If the surface dries out before it can cure, it can lead to "plastic shrinkage cracks" and a weaker surface layer. We can advise on the best time of day to pour and the right curing methods to use.

- Cold Weather: While less common, temperatures below 50°F slow down hydration considerably. Below 40°F, the reaction practically stops. If the water in the mix freezes, it can expand and permanently damage the concrete's internal structure.

2. The Right Concrete Mix Design

The type of mix you use matters. High-strength mixes may reach their design strength faster. Mixes with certain admixtures, like accelerators or retarders, are specifically designed to speed up or slow down the set time to accommodate project or weather conditions. The experts at Concrete Gilbert help you select the right mix for your timeline and our local environment.

3. Slab Size and Project Dimensions

A massive, thick industrial slab will cure differently than a thin 4-inch patio. The surface-area-to-volume ratio affects how quickly moisture can escape. We help you understand how your project's specific dimensions will impact the curing strategy.

From Curing Techniques to Final Preparation

Navigating these factors can seem complex, but you don’t have to do it alone. At Concrete Gilbert, we act as your project partners, providing practical advice tailored to your situation.

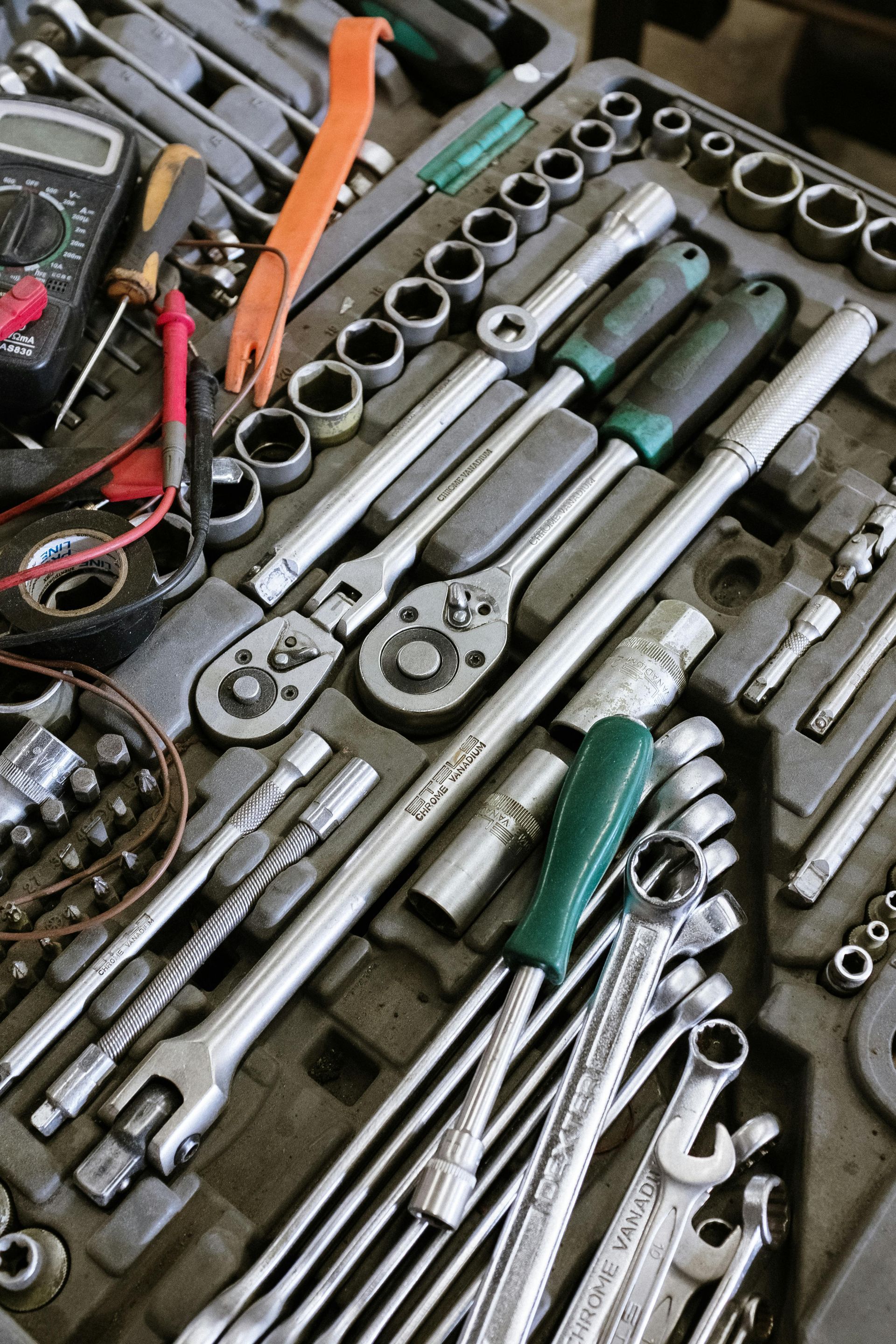

Curing Techniques and Calculations

We provide not just the concrete but the know-how to cure it properly. We can advise you on the best methods for your project, whether it is using curing compounds that form a protective film, covering the slab with plastic sheeting, or periodic watering with a sprinkler (wet curing). We can also help you calculate the amount of curing compound needed based on your square footage, taking the guesswork out of the process.

Preparing for Post-Curing Life

Reaching the 28-day mark is a huge milestone, but the job isn’t quite done. To ensure your concrete looks great and lasts for decades, a few final preparation steps are highly recommended.

- Sealing Your Concrete: We strongly advise sealing your new concrete. A good sealer acts as a protective barrier against stains from oil or grilling, and it makes cleaning much easier. It also protects the surface from the harsh sun. We can recommend the right type of sealer for your project and advise on the proper time to apply it after the cure is complete.

- Applying Finishes: If you plan to stain or paint your concrete, it’s crucial that the slab is sufficiently dry. Applying a coating too soon can trap moisture, causing the finish to fail. We provide guidance on how to ensure your slab is ready for any decorative treatments.

Your Partner for a Strong Finish

Your concrete project is a significant investment of time, money, and effort. The final, critical step of allowing it to cure properly is what ensures that investment pays off for decades to come. Rushing the process is a recipe for disappointment and potential failure.

At Concrete Gilbert, we are committed to seeing your project through to a successful conclusion. We provide the high-quality materials and the expert guidance you need to understand and manage the concrete curing process effectively. Have questions about your next concrete project? Contact Concrete Gilbert today for expert advice on materials, calculations, and proper curing techniques!

Meta Information

Meta Title: A Guide to Concrete Curing | Concrete Gilbert

Meta Description: How long does concrete take to cure? Learn the difference between drying and curing, key timelines, and get expert tips from Concrete Gilbert.